In this post, I will discuss the future of manufacturing and explore cutting-edge technology.

Cutting-edge developments are about to trigger a technological revolution in the manufacturing sector.

Innovations in artificial intelligence, 3D printing, robotics, quantum computing, and the Industrial Internet of Things are revolutionizing the design, manufacturing, and maintenance of products.

This article examines these innovative technologies, highlighting their effects and possible applications in the manufacturing sector.

Adopting these technologies can help industries remain competitive, meet the evolving needs of a rapidly changing market, and ensure that production processes are robust and future-ready.

Table of Contents

Artificial Intelligence (AI)

Manufacturing is undergoing a transformation as a result of artificial intelligence (AI), which enhances productivity and streamlines processes. Artificial intelligence (AI) is utilized in predictive maintenance, where data analysis is employed to anticipate equipment breakdowns before they occur, thereby minimizing downtime and repair expenses.

AI also raises the bar for quality control by utilizing machine learning algorithms to find product flaws and guarantee superior quality. Artificial intelligence (AI) technologies are starting to operate autonomously in smart factories, modifying operations in real-time to increase productivity.

Artificial Intelligence (AI) in supply chain management facilitates waste reduction, inventory control, and demand forecasting. AI technology will continue to transform manufacturing as it develops, making processes more efficient, quick, and intelligent.

Additive Manufacturing (3D printing)

3D printing, also referred to as additive manufacturing, is completely changing the way how items are created and developed. This technology enables you to produce complex, unique parts swiftly and affordably. It is already utilized in prototyping, enabling quick iteration and testing of concepts.

In production, 3D printing allows for on-demand manufacturing, which reduces the need for big stocks. 3D printing in the medical field, also known as bioprinting, has applications in medicine, including the creation of bespoke implants and tissue.

It is anticipated that 3D printing technology will expand into larger, more sophisticated industries, such as aerospace and construction. This breakthrough is crucial to the production of the future, as it enables previously unheard-of levels of efficiency and personalization.

Industrial Internet of Things (IIoT)

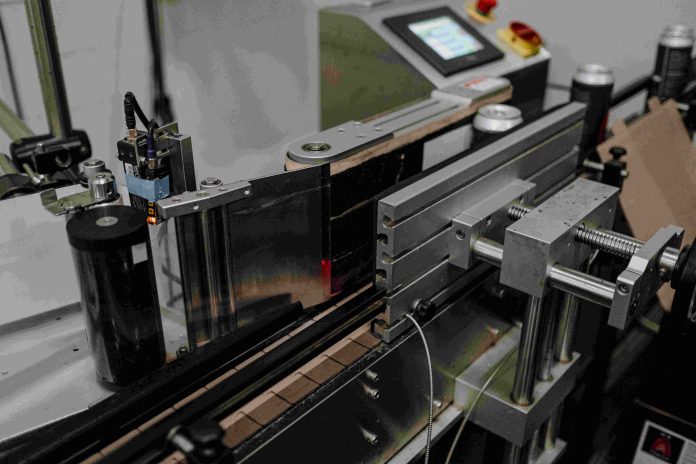

The Industrial Internet of Things (IIoT) integrates connected devices and systems into manufacturing, enabling the creation of smart factories. IIoT makes data analytics and real-time monitoring possible, providing you with production-wide insights.

Machine sensors monitor operations and forecast maintenance requirements, reducing downtime and extending equipment life. You can increase overall efficiency, track inventories in real-time, and manage energy use with IIoT. The information gathered helps improve production, reduce expenses, and inform well-informed decisions.

As IIoT technology advances, completely autonomous, interconnected factories with seamless machine-to-machine communication will become the norm, driving innovation and continuous improvement in manufacturing processes.

READ ALSO: Acheron Instruments: Leading the Future of Surgical Instrument Manufacturing in Pakistan

Robotics and Automation

Production lines are being transformed by robotics and automation, which are at the forefront of modern industry. Robots enhance productivity and safety by automating dangerous and repetitive tasks. Cobots, or collaborative robots, assist humans in the workplace, increasing efficiency and flexibility.

Automation systems ensure uniformity and accuracy in production processes. You benefit from improved product quality and reduced labor costs. Advanced robotics with AI capabilities is a trend of the future that will enable increasingly complex activities to be mechanized.

The manufacturing landscape will continue to change as robotics and automation technology advances, spurring efficiency and creativity. Accepting these innovations guarantees that your business processes remain flexible and competitive.

Quantum Computing

Quantum computing has the potential to transform manufacturing by tackling complex problems far more efficiently than traditional computers. Quantum computing can be utilized to reduce expenses, enhance efficiency, and optimize supply chains.

It can accurately simulate molecular structures, which helps in the creation of novel materials and goods. Sensitive manufacturing data is protected by sophisticated encryption techniques used in quantum computing, which improves data security.

Although it is still in its infancy, quantum computing appears to have a bright future in manufacturing. Integrating quantum computing manufacturing 4.0 into systems will enhance automation, real-time data processing, and intelligent decision-making.

As this technology advances, it will open up previously unimaginable possibilities for breakthroughs, providing you with access to unmatched processing capacity and propelling the subsequent wave of industrial advancements.

Conclusion

The integration of cutting-edge technologies has opened up a bright and promising future for the manufacturing industry. Robotics, quantum computing, the Industrial Internet of Things, 3D printing, and artificial intelligence are not merely trends; they are changing the industry.

These technologies will spur additional developments that will make manufacturing more efficient, quick, and sustainable as they continue to advance.

To successfully navigate the complexity of the contemporary manufacturing landscape and take advantage of the development and innovation opportunities it brings, it is imperative to embrace these changes.

INTERESTING POSTS

About the Author:

John Raymond is a cybersecurity content writer, with over 5 years of experience in the technology industry. He is passionate about staying up-to-date with the latest trends and developments in the field of cybersecurity, and is an avid researcher and writer. He has written numerous articles on topics of cybersecurity, privacy, and digital security, and is committed to providing valuable and helpful information to the public.