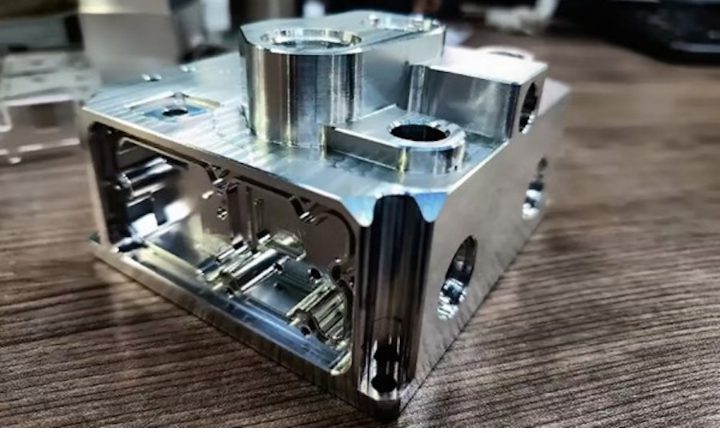

In this post, I will talk about practical CNC cost control insights.

In the modern competitive manufacturing world, every shop is struggling to keep costs low and profits high. Practical CNC cost control Insights from WayKen show real ways of stopping money leakages that happens every day.

WayKen rapid manufacturing helps companies to save on material, time, and tools without decreasing quality. Our services offer parts at a faster and more cost-effective rate than traditional methods. Practical CNC cost control Insights from our company are based on years of experience at the shop floors.

We converts common waste into actual savings. Custom CNC machining services make these changes easy for any team.

Table of Contents

Key Cost Pain Points

1. Low Material Utilization

Poor utilization of materials is among the biggest hidden cost. Many shops purchase expensive blocks and then discard 70% of them as chips – they are essentially throwing money away. WayKen rapid manufacturing frequently faces this problem and utilizes custom CNC machining services to better plan and maximize the usable material.

2. Excessive Machining Hours

Long machining cycles hurt profitability. Whereas when a part is running for eight hours instead of three, it results in increased costs on electricity, labor, and spindle time. We pay a lot of attention to the utilization of the occupied machine time, and the custom CNC machining service aims to abbreviate the cycle to achieve instant saving.

3. Rapid Tool Wear

Unexpected tool wear causes overstated tool budgets. A $600 insert that lasts only for 20 parts doubles or triples costs. Frequent changing of tools also means more down-time. WayKen rapid manufacturing chooses better tool grades, and the services that prolongs the life of CNC tooling by optimized cutting parameters.

4. High Pressure Control of Quality

Too much inspection time incurs hidden costs. Rechecking each and every feature reduces the pace of production increasing the rework and scrap rates. We create high quality designs for the machining process itself. With this approach, the amount of redundant final inspections are reduced with custom CNC machining services.

Practical Solutions and Implementation Measures

Practical CNC cost control Insights from WayKen offer easy to understand fixes that immediately work. We apply these ideas on each and every job and turn pain points into profits.

1. Material and Fixture Optimization

Start with smart nesting and multi part fixtures. Fit more parts into one block and material savings of 25-40% are instantly available. We use of advanced software for perfect nesting. Custom CNC machining services redesign the fixtures so that one set-up machines five or ten pieces instead of one.

Vacuum fixtures and modular clamps are useful to reduce waste even further. Leave only the precise amount of stock you need – sometimes just 1mm more. Roughing does not remove as much material and finishing remains safe and accurate.

2. Process Optimization

Toolpath refinement frees up hours on each job. Old CAM programs produce long air cuts which are time-wasting. Modern adaptive clearing – the tool is kept in the material with constant chip load. Cycle times drop 30–50% right away. WayKen’s rapid manufacturing updates toolpaths every week for optimal results. Custom CNC machining services test all new files before running them.

Use combination tools and consolidated operations wherever possible. One drill mill tool can perform two functions at once. Less tool changes, the spindle will run more and sit less. Roughing and semi-finishing are often done by the same holder. This simple change reduces hours off of complex parts.

3. Tooling and managing parameters

Choose the right insert grade at the beginning. Cheap inserts wear out in a matter of minutes with hard materials. Premium grades cost more initially, but last five times longer. Cost per part reduces dramatically. WayKen rapid manufacturing conducts actual tests on all materials. Custom CNC machining services keep notes of actual wear information for upcoming jobs.

Lower surface speed 10% and increase feed 20% – this is the sweet spot where tool life is doubled and cycle time remains the same or decreases. Many shops operate too aggressive and pay for later with broken tools. High-pressure through-tool coolant chips provide better edge life. Clean coolant systems allow machines to operate longer shifts with no trouble.

4. In-Process Monitoring/Quality Control

Add touch probes directly on the machine. Examine critical features between operations and discover errors early. Scrap drops from 8% down to less than 1% almost overnight. WayKen rapid manufacturing probing every important batch. Custom CNC machining services believe in in-machine measurement rather than final inspection lines.

Tool breakage detection using lasers or power monitors prevent tool breakage crashes instantly. No more scrapped out parts from broken tools. Renishaw spindle probes automatically update tool length every 20 parts, and automatically compensate for thermal growth. Tolerance remains within the range of +-0.01mm in all shifts.

5. Production Planning and Scheduling

Group similar materials together to reduce the setup time by 60%. Running all aluminum jobs, then all steel jobs. Tooling is longer lasting and changeovers are quicker. WayKen rapid manufacturing schedule smartly every day and finish batches quickly without overtime.

Balance load between all machines in real-time. Never let a 5 axis machine sit and wait while 3 axis machines wait. Keep in stock raw material of exact size to avoid emergency shipping fees. Planning four weeks in advance eliminates panic and additional expenditures.

Results That Matter

Shops that follow Practical CNC cost control Insights from WayKen real numbers change fast. There is a 30% reduction in material waste, a 35% reduction in machining time, a 50% reduction in the cost of tooling per part, and a scrap rate below 1%. And they certify that profit margin is growing 15-25% on the same jobs.

WayKen rapid manufacturing makes these savings every single day in our 35,000 sq ft facility. Custom CNC machining services offer clients consistent results, regardless of their location worldwide. Start with one part number today. Measure before and after. You will see improvement in the first week.

Practical CNC cost control Insights from WayKen work because they are derived from real shop and not from theory. Small changes mean a lot of money. Shops that act now are always ahead tomorrow.

INTERESTING POSTS

About the Author:

John Raymond is a cybersecurity content writer, with over 5 years of experience in the technology industry. He is passionate about staying up-to-date with the latest trends and developments in the field of cybersecurity, and is an avid researcher and writer. He has written numerous articles on topics of cybersecurity, privacy, and digital security, and is committed to providing valuable and helpful information to the public.