Finding the right electronics manufacturer can make all the difference between a product that performs flawlessly and one that struggles to meet expectations. As industries—from automotive to medical technology—continue to evolve, the demand for precision, reliability, and efficiency in electronic manufacturing has never been higher.

Choosing a reliable electronics manufacturer is not just about comparing quotes or turnaround times. It’s about evaluating experience, technological capability, quality control, and the ability to scale production without compromising performance.

In Australia, where the electronics industry is gaining global recognition for innovation and quality, understanding what sets top manufacturers apart can help businesses make smarter, long-term decisions.

This comparison guide will help you navigate key factors to consider before partnering with an Australian electronics manufacturer and how to identify one that aligns perfectly with your project’s goals.

Table of Contents

The Growing Electronics Manufacturing Landscape in Australia

Australia has emerged as a strong contender in global electronics manufacturing. From renewable energy systems and telecommunications to industrial automation and consumer electronics, local companies are designing and producing high-quality electronic solutions that meet international standards.

Unlike low-cost offshore facilities, Australian manufacturers focus heavily on precision, safety compliance, and sustainable practices. Many adhere to ISO certifications, RoHS compliance, and strict testing protocols—ensuring every product meets performance expectations in demanding environments.

This focus on quality over volume makes Australian electronics manufacturing particularly appealing for industries that prioritise durability, traceability, and long-term reliability.

What Makes a Good Electronics Manufacturer

When comparing electronics manufacturers, it’s essential to look beyond cost. The cheapest option can often lead to delays, rework, or product failures. Instead, consider these key attributes that define top-tier manufacturers:

1. Technical Expertise

The best manufacturers employ highly skilled engineers and technicians who understand both design and production. Their expertise covers circuit design, surface-mount technology (SMT), through-hole assembly, and automated inspection systems. This ensures that every stage—from prototype to mass production—meets tight tolerances.

2. End-to-End Capability

Efficiency comes from working with a manufacturer that offers a complete solution. Full-service facilities handle everything in-house—from design assistance and prototyping to sourcing, assembly, and testing. This eliminates communication gaps and accelerates time-to-market.

3. Quality Assurance and Testing

Strong quality control processes are non-negotiable. Reputable manufacturers conduct multiple testing phases, including automated optical inspection (AOI), in-circuit testing (ICT), and functional testing (FCT), to ensure every board performs as intended.

4. Supply Chain Reliability

Global supply chain issues have highlighted the importance of local partnerships. Manufacturers that maintain trusted supplier relationships can secure components faster and mitigate shortages, keeping projects on schedule.

5. Scalability

A good partner should adapt to your needs—whether you require small prototype batches or large-scale production runs. Scalable manufacturing capabilities allow for cost efficiency and flexibility as your business grows.

Key Considerations When Comparing Manufacturers

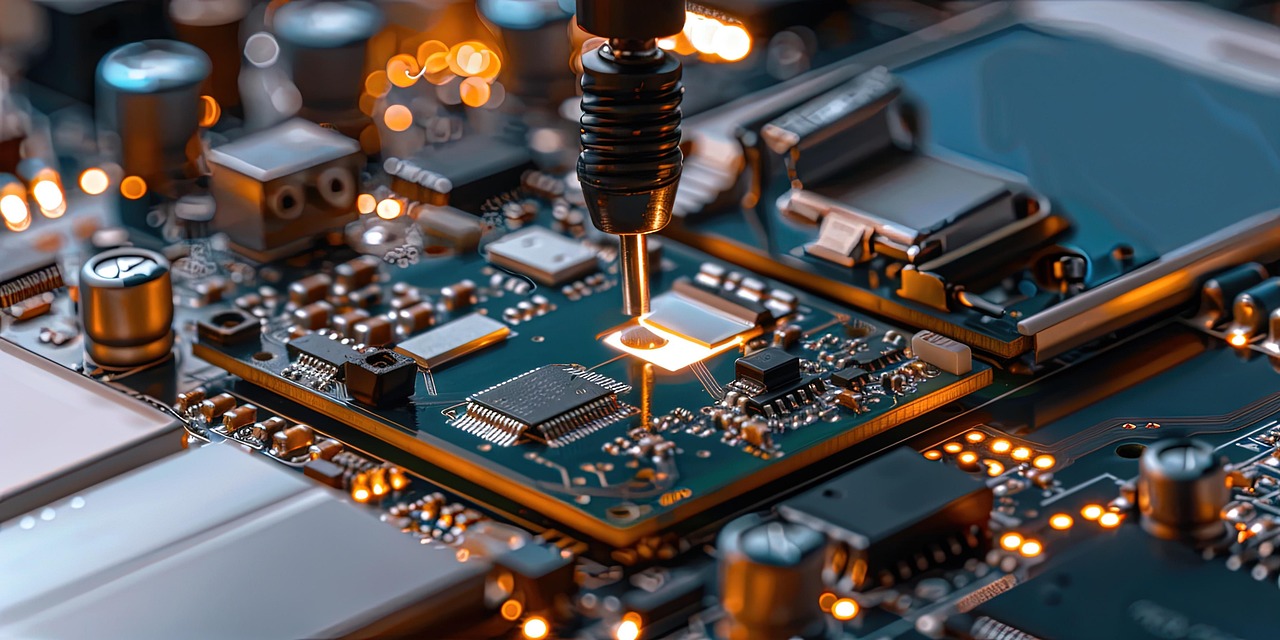

Production Capabilities

Evaluate the size, equipment, and technical range of each facility. Modern manufacturing lines should include automated pick-and-place systems, reflow ovens, and solder paste inspection machines to guarantee precision.

Design Support

Some manufacturers offer design and engineering services to refine your schematic and layout before production. This reduces the risk of costly design errors and ensures the product is optimised for manufacturability.

Lead Times and Responsiveness

Speed is crucial—but not at the expense of accuracy. The best manufacturers balance efficiency with quality by maintaining open communication and providing realistic production schedules.

Certifications and Standards

Look for manufacturers certified under ISO 9001 or similar quality management systems. Certifications demonstrate compliance with rigorous standards, especially for industries like defence, aerospace, or healthcare.

Environmental and Ethical Responsibility

Sustainability is increasingly important in electronics production. Top Australian manufacturers adopt eco-conscious practices—such as responsible material sourcing and waste reduction—while adhering to safety and environmental regulations.

Comparing Service Specialisations

Each manufacturer may focus on specific service categories. Understanding what they specialise in helps match your project with the right partner.

- Prototyping Specialists: Ideal for startups and R&D projects needing small quantities for testing.

- High-Volume Production: Suitable for established brands scaling up mass production.

- Custom Electronics: Focused on bespoke designs, embedded systems, and one-off assemblies.

- Repair and Rework: Some manufacturers provide maintenance and support for existing products.

Depending on your goals, you may need a company that balances both rapid prototyping and scalable production to handle future growth seamlessly.

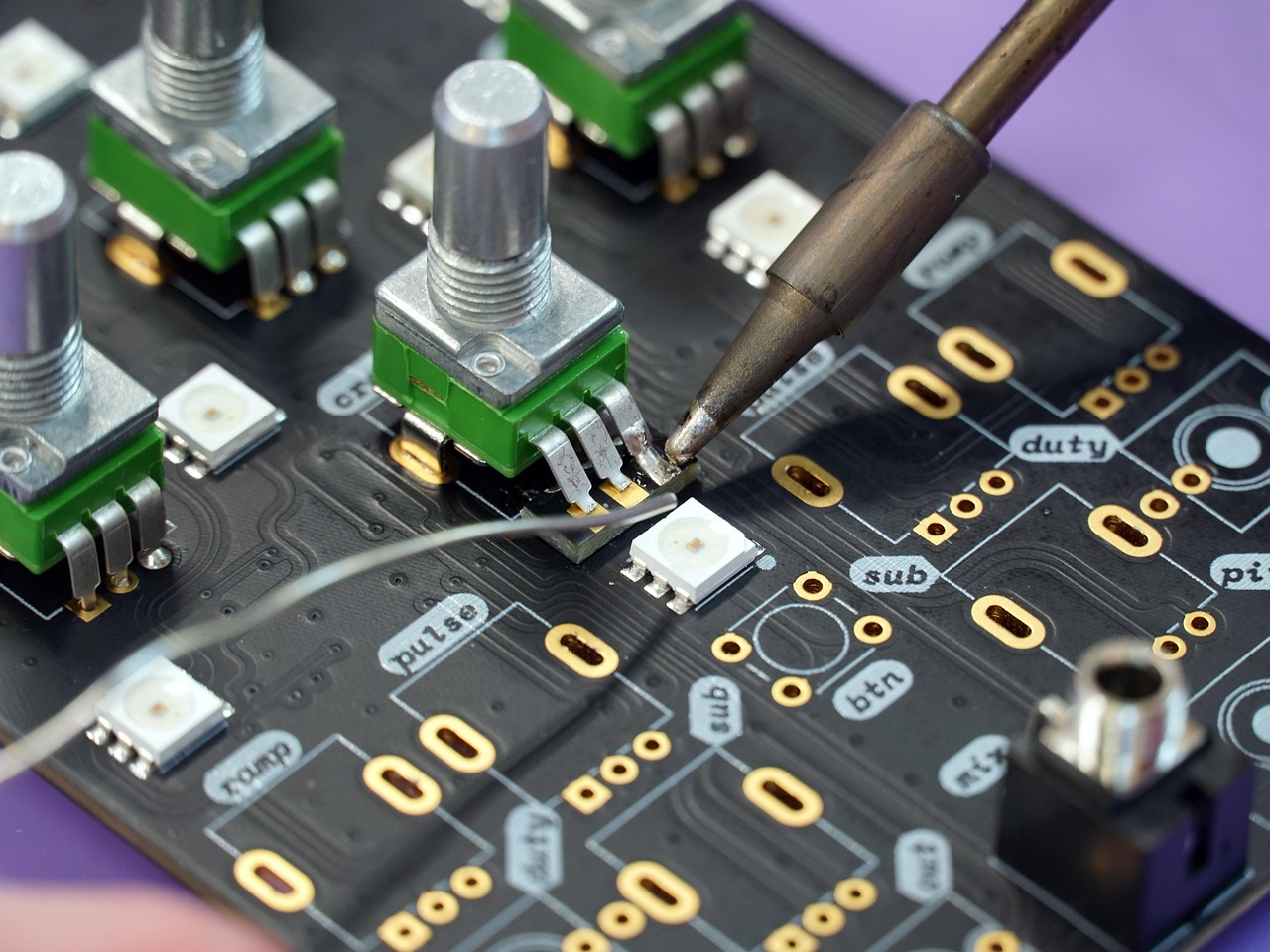

Why PCB Assembly Defines Manufacturing Quality

At the heart of every electronic product lies its printed circuit board (PCB). A manufacturer’s PCB capabilities often reflect its overall quality and technological sophistication.

Professional printed circuit board assembly ensures that each component—whether surface-mounted or through-hole—is placed with accuracy, soldered to perfection, and rigorously tested. This precision is vital for performance, safety, and product longevity.

Leading Australian manufacturers use automated pick-and-place machines, reflow ovens, and high-resolution inspection tools to achieve consistency. They also maintain strict electrostatic discharge (ESD) protection procedures, ensuring sensitive components are handled safely during production.

PCB assembly quality often determines the overall reliability of your final product—making it a critical factor in any manufacturer comparison.

Advantages of Working with Australian Manufacturers

- Superior Quality Control: Local facilities operate under strict regulatory standards, ensuring consistent results.

- Faster Communication: Time zones and proximity make collaboration more efficient.

- Shorter Lead Times: Reduced shipping distances mean faster delivery.

- Transparency: Australian companies prioritise traceability, accountability, and ethical production.

- Support for Local Innovation: Partnering with domestic manufacturers contributes to the growth of Australia’s technology ecosystem.

These advantages often outweigh marginal cost differences compared to offshore alternatives, especially when long-term reliability and support are priorities.

How to Choose the Best Fit for Your Project

- Request Case Studies: Review past projects similar to yours. This helps evaluate experience in your industry.

- Inspect Facilities: Whenever possible, visit the manufacturer’s facility to assess equipment, workflow, and cleanliness.

- Evaluate Communication: Reliable manufacturers maintain transparency, providing updates and quick responses.

- Compare Value, Not Price: The cheapest option is rarely the most cost-effective in the long run.

- Ask About Support: Post-production services—such as testing, packaging, and logistics—can streamline your entire process.

Conclusion

Choosing the best electronics manufacturer in Australia requires more than comparing quotes—it’s about aligning expertise, technology, and reliability with your project’s demands.

Manufacturers like Precision Electronics exemplify the advantages of local, high-quality production—combining advanced technology, experienced engineers, and rigorous quality control to deliver results that meet the highest standards.

In a world where efficiency and precision define success, partnering with a capable, trustworthy manufacturer ensures your product performs as designed—today, tomorrow, and for years to come.

INTERESTING POSTS

About the Author:

Chandra Palan is an Indian-born content writer, currently based in Australia with her husband and two kids. She is a passionate writer and has been writing for the past decade, covering topics ranging from technology, cybersecurity, data privacy and more. She currently works as a content writer for SecureBlitz.com, covering the latest cyber threats and trends. With her in-depth knowledge of the industry, she strives to deliver accurate and helpful advice to her readers.